Corten steel, also known as weathering steel, has captivated designers and architects with its rugged, industrial aesthetic. Its signature rusty appearance isn’t just for looks—it plays an essential role in protecting the material from further corrosion. But how does Corten steel actually work, and what sets it apart from other metals? In this post, we’ll explore the science behind Corten steel and how it naturally protects itself from rust and corrosion.

1. What is Corten Steel?

Corten steel is a group of steel alloys developed to resist the damaging effects of weathering. Unlike regular steel, which corrodes over time when exposed to the elements, Corten steel is engineered to form a stable layer of rust that acts as a barrier against deeper corrosion.

The name “Corten” comes from its two key properties:

- COR (corrosion-resistant)

- TEN (tensile strength)

These properties make Corten steel particularly useful in outdoor applications, where other types of steel would quickly deteriorate due to weather exposure.

2. The Patina Formation: Nature’s Protective Layer

When Corten steel is exposed to the atmosphere, it undergoes a process known as oxidation, where the iron in the steel reacts with oxygen and moisture in the air. This reaction forms an outer layer of rust. While most metals continue to corrode and weaken after forming rust, Corten steel behaves differently.

Here’s how it works:

- Initial Rusting Phase: In the early stages of exposure, Corten steel will start to rust just like ordinary steel. This happens as the iron in the metal reacts with air and moisture, creating a reddish-brown layer of iron oxide.

- Formation of a Protective Patina: As the rusting process continues, the outer rust layer becomes more uniform and begins to stabilize. This is where Corten steel’s magic happens—the outer rust layer gradually transforms into a dense, protective barrier known as a patina.

- Prevents Further Corrosion: The patina that forms on Corten steel serves as a shield that prevents moisture and air from reaching the underlying steel. Once fully formed, this layer halts further rusting, protecting the structural integrity of the material. This is a key difference between Corten steel and regular steel, which continues to rust and degrade over time.

3. The Alloying Elements Behind Corten Steel’s Durability

What gives Corten steel its unique properties? The secret lies in its composition. Corten steel contains a variety of alloying elements that promote the formation of a stable patina and resist further corrosion.

- Copper (Cu): One of the primary elements that gives Corten steel its rust-resistant properties is copper. Copper plays a crucial role in speeding up the oxidation process while helping to create a tighter, more uniform patina that sticks to the surface of the steel.

- Chromium (Cr): Another important element in Corten steel is chromium. It works in conjunction with copper to ensure that the rust layer doesn’t flake off like it would on standard steel. Instead, chromium helps the patina remain tightly bonded to the surface.

- Nickel (Ni) and Phosphorus (P): Nickel and phosphorus are also added to the alloy to enhance the material’s toughness and weather resistance. These elements contribute to the slow, even formation of the protective patina, making it more durable and long-lasting.

Together, these alloying elements interact to create a self-protecting steel that becomes more resilient as it ages.

4. Why Corten Steel Needs Exposure to the Elements

The rusting process that protects Corten steel is dependent on regular exposure to moisture and air. In environments where the material alternates between wet and dry cycles, the patina will form more effectively. For example, Corten steel will rust and protect itself faster in outdoor settings where it’s exposed to rain, followed by periods of drying.

However, it’s important to note that continuous exposure to moisture, such as being submerged in water or exposed to highly humid environments, can cause Corten steel to rust beyond the protective stage. That’s why proper drainage and installation are important considerations when using Corten steel in landscaping or construction projects.

5. Stages of Patina Development

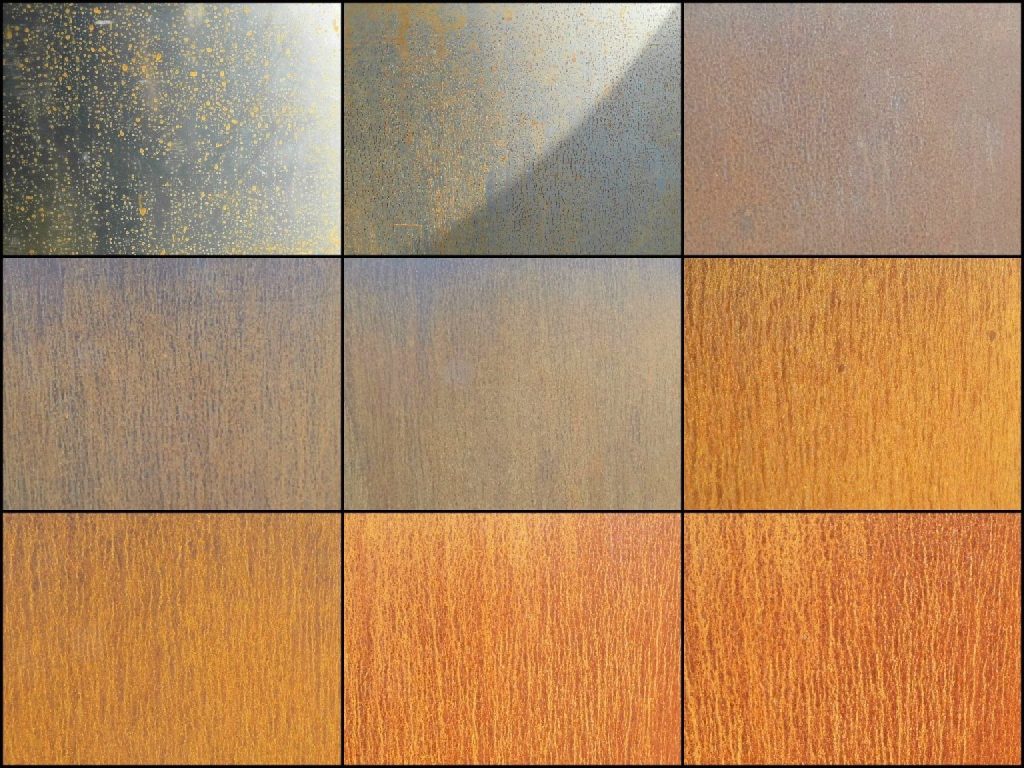

Corten steel’s appearance changes over time as the patina matures. The entire process typically takes anywhere from 6 months to 2 years, depending on environmental conditions. Here are the typical stages:

- Stage 1: In the first few weeks or months, the steel will develop a reddish-orange rust as it begins to oxidize. This phase is characterized by uneven and sometimes patchy rust formation.

- Stage 2: As more time passes, the rust will darken and become more uniform across the surface. This darker, richer rust color is a sign that the patina is stabilizing.

- Stage 3: After full patina formation, the Corten steel develops a consistent, dark brown or bronze color. At this stage, the patina is fully protective, preventing further corrosion.

6. Applications of Corten Steel

The self-protecting properties of Corten steel make it ideal for a variety of outdoor applications, including:

- Garden Edging: Its durable and low-maintenance qualities make Corten steel perfect for garden beds and landscape edging, providing a strong barrier that won’t degrade over time.

- Water Features: The character development that comes with Cortens’ exposer to the elements, makes for a very durable and ever-changing design element in your landscape.

- Planters: We can’t emphasize the sustainability and longevity of these planters! The rust patina does not effect any plants or soil.

- Architectural Features: Corten steel is widely used in modern architecture for its industrial look and ability to withstand weather conditions with minimal maintenance.

- Bridges and Large Structures: Thanks to its high tensile strength and resistance to weathering, Corten steel has been used in the construction of bridges and other large structures where long-term durability is essential.

7. Caring for Corten Steel: Does It Need Maintenance?

One of the benefits of Corten steel is its low maintenance. Once the patina has fully formed, the material requires very little care. However, it’s important to:

- Ensure proper drainage: To prevent water from pooling, especially in garden installations, as excessive moisture can disrupt the protective patina.

- Rinse off salt or pollutants: In coastal areas, rinsing off salt or chemicals from the surface occasionally can help prevent uneven patina formation.

Corten steel is a fascinating material that combines aesthetic appeal with scientific ingenuity. Its ability to form a self-protecting layer of rust allows it to maintain its structural integrity while adding a unique, weathered charm to any outdoor or architectural space. By understanding the science behind Corten steel’s patina, you can better appreciate its long-lasting durability and beauty in landscape design or construction projects.